Defender™ Automated Barrier Door

Benefits

Anywhere that a machine operator interfaces with a machine, robot or process is an ideal application for the Defender™, including:

- Automotive

- Industrial Manufacturing

- Steel and Aluminum Works

- Warehouse and Logistics

- Agriculture

- Aerospace and Defense

- Machining

Product Specifications:

- Minimum size of 3’ x 3’ (610 mm x 914 mm), Maximum size of 16’ x 16’ (4877 mm x 4877 mm)

- 40" [1020 mm] per second operation; Up to 60" [1524 mm] per second with optional variable frequency drive.

- Armorplex™ Curtain Material: Durable, Resilient 40oz flame resistant (NFPA 701) high tensile ASTM tested black curtain material.

- Fully Sealed UHMW Barrier Tabs™; 450 lbs. (204 kg) tear-out force.

- 1 HP (0,75 kW) Motor Assembly with 20 N*m brake with lockable hand release lever and corrosion protection, TEFC. IP 55 Enclosure rating, UL and CSA listed. NEMA 56C output. Multiple motor locations and orientations.

- Fully Sealed Barrier Tabs prevent access to hazard and act as barrier with 450 lbs. (204 kg) tear out strength.

- View our Defender™ sell/spec sheet for more product specifications.

Compliance and Standards:

Switches/controls capable of reaching Cat 4 (per 954-1), PLe (per ENISO 13489-1) and/or SIL 3 (per EN62061) when integrated properly.

-

Safety Distance Formula Info:

- EN ISO 13857 Safety of Machinery - Safe distances to prevent hazard zones being reached by upper/lower limbs. and EN ISO 13855

- Safety of Machinery - Position of safeguards with respect to the approach speeds of parts of the body.

- Manufactured under ISO 9001 Specifications with a rugged construction.

Additional highlights:

- Multiple motor positions to best fit your application.

- Easy Installation with minimal components.

- Optional control boxes include:

- Full Open-Close-Stop Push Button Relay Control Box.

- Patented i-COMM™ Digital Communication Control Box and Plug-N-Play Integrator Control Box.

- Limited one year warranty SOP.

- Custom manufactured to exact size requirements.

- HD Motor/Brake/Gear box suited for millions of cycles.

- Optional stopping photo-eye strip.

- Soft Bottom Edge - Gravity down operation. Patented switch design integrated into curtain guide.

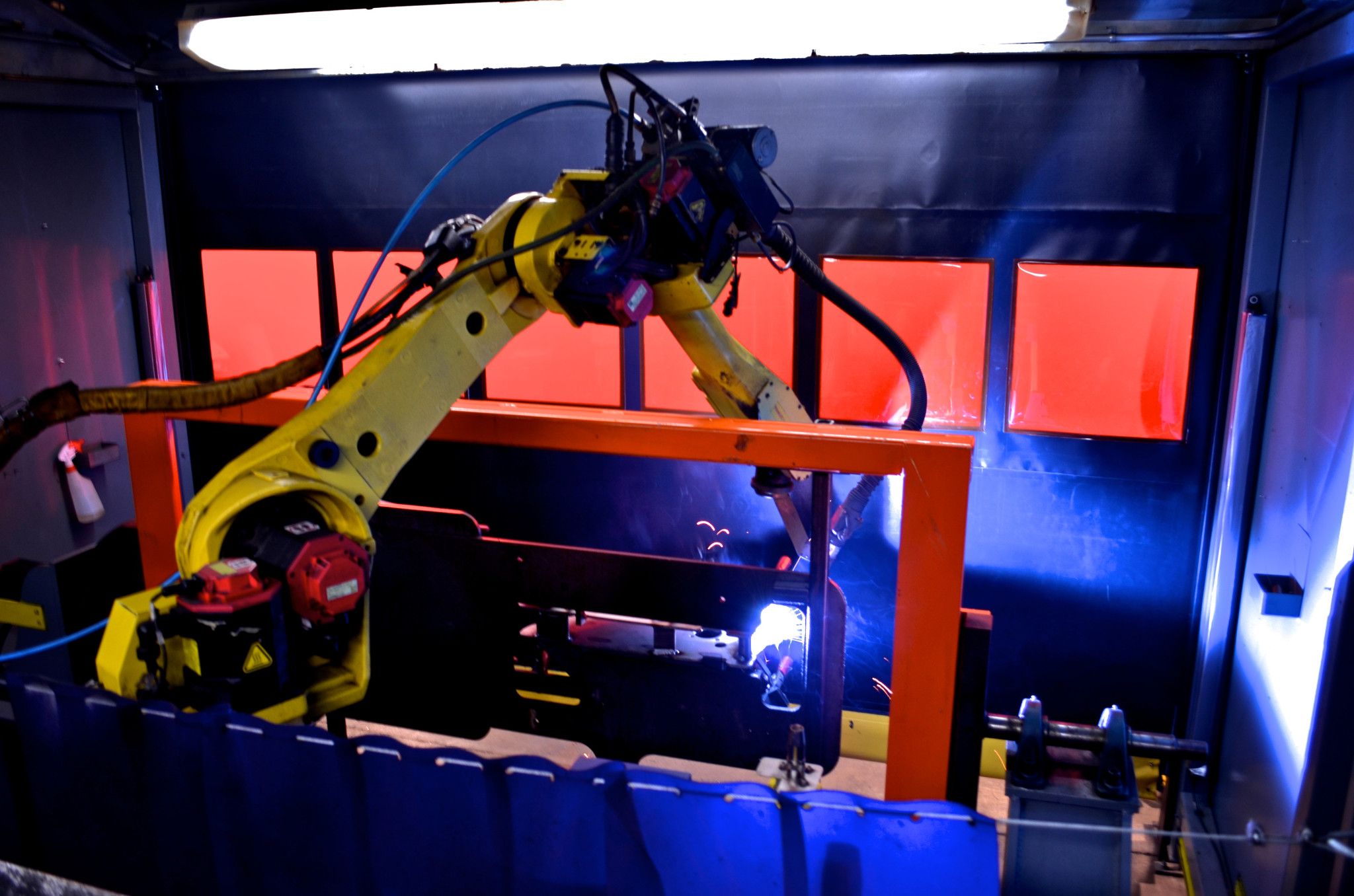

Visibly safer than light curtains, the Defender™ automated barrier door combines safety interlock switches/controls capable of achieving up to PLe, Category 4 level safety with a movable physical barrier, restricting access to dangerous machine movement while simultaneously protecting your most valuable asset – your people.

- Guards your machinery and helps protects your employees.

- Contains application driven hazards including weld flash/sparks/smoke, mist, flying debris and more.

- Reduces footprint of manufacturing cell by locating closer to hazard.

- Automated to the process to reduce operator fatigue.

- Increases productivity! Door provides clear visual that operator should be on task.

- Physical machine guard provides more benefits than light curtains (see: Benefits of Physical Machine Guards Versus Light Curtains)

- Proven, Safe, Reliable Design.

Gallery

Need more info?

Fill out the form below and one of our reps will reach out to you.

improving industrial safety, security and productivity worldwide THROUGH QUALITY AND INNOVATION

WANT MORE INFORMATION?

Fill out the form below and one of our reps will reach out to you.

Thank you for filling in the form.

Someone from our team will be in touch with you shortly.